Feb 02,2026

1. Functionality first: Early designs were mainly practical

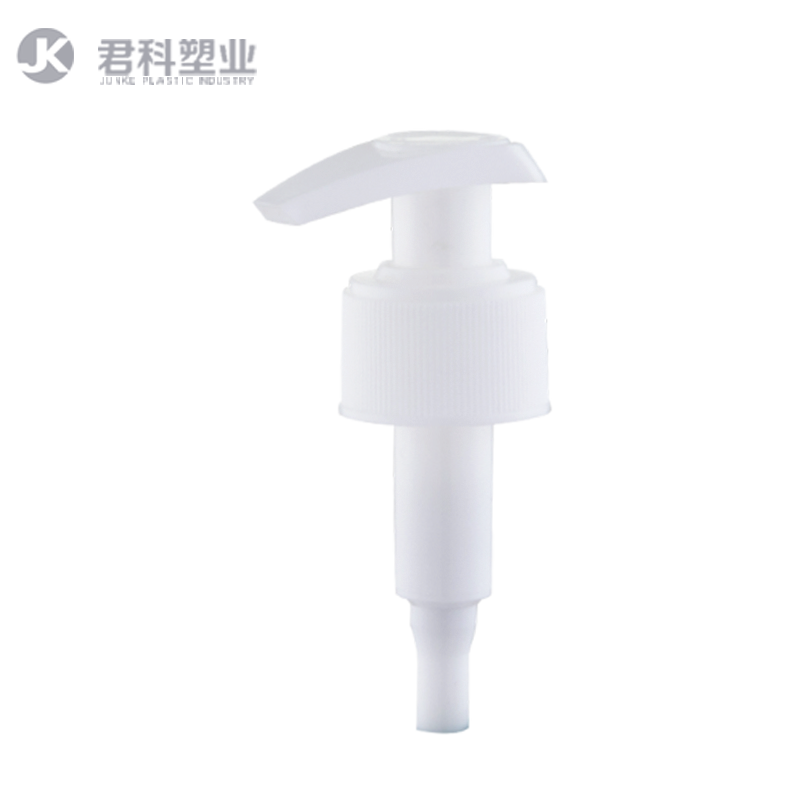

The initial lotion pump design appeared in the late 1970s and early 1980s. At that time, the market demand was mainly "simple and reliable", and functionality was the only core of the design. Typical features include:

The pump body has a simple structure: it is mainly composed of a pump head, a spring, a piston, a straw and a threaded interface;

The material is mainly PP (polypropylene): it has strong chemical resistance, low cost, and is suitable for most daily chemical liquids;

The dispensing volume is fixed: 1ml or 2ml of liquid is dispensed each time it is pressed, which is suitable for high-frequency use products such as shampoo and detergent;

Basic sealing guarantee: although there is no lock, the early pump head relies on spiral closure to prevent leakage.

The advantages of this pump head are stability, low manufacturing cost, and easy mass production, so it quickly became popular.

2. User experience upgrade: moving towards humanized operation

With the changes in lifestyle and the rapid rise of the female market, the user experience of lotion pumps has been mentioned in an unprecedented important position. Manufacturers began to pay attention to "who is using it, how to use it, and whether it is comfortable to use", and a series of detail optimizations followed:

One-touch lock design: prevent accidental touch during transportation or travel to cause liquid spillage, and improve safety;

Press resistance optimization: improve the spring rebound coefficient, making finger pressing more labor-saving, especially suitable for frequently used skin care products;

Pump head angle adjustment: change from vertical liquid discharge to 10°–30° oblique liquid discharge, so that users can operate with one hand without additional tilting of the bottle;

Anti-slip design: add texture or anti-slip grooves on the surface of the pump head to improve the feel and operation stability;

Improved distribution accuracy: control the pressure feedback of the pump core to make each use more stable and avoid excessive liquid discharge at one time.

This stage marks the transition of Plastic Screw Lotion Pump from "technology-led" to "user experience-driven".

3. Fusion of aesthetics and brand tone: appearance becomes the focus of design

When consumers begin to pursue "good looks" in addition to "easy to use", lotion pumps officially enter the track of "appearance economy". Brands began to realize that packaging is an important contact point for user cognition. As the focal part of the bottle's visual appearance, the pump head has also become more design-oriented:

Diversified surface processes: such as metal plating (looks like metal but is actually plastic), pearlescent coating, matte paint, transparent pump cover, etc., bring a high-end visual experience;

Color customization: support Pantone color number customization, coordinate or contrast with the bottle color, and reflect the brand tone;

Pump type innovation: such as gooseneck, flat, and arc-shaped pump heads, which are both beautiful and easy to operate, creating unique recognition;

Detailed LOGO embossing: through laser engraving or mold embossing technology, the brand logo is reflected on the pump head or pump cover to enhance brand memory;

Uniform design of the set: using a consistent style of pump heads in multiple categories of products (such as washing and care combinations, skin care combinations) to enhance the sense of series and shelf appeal.

The design at this stage not only serves the use function, but also begins to assume the responsibility of brand visual communication and user emotional connection.

4. Environmental awakening: sustainable design becomes a new focus

In recent years, sustainable development has become a key theme in the global packaging industry. Plastic Screw Lotion Pump is also actively responding to environmental trends and promoting green transformation of materials, structures and life cycles:

Metal-free spring structure (Metal-Free Pump): The metal spring in the traditional pump head makes it difficult to recycle and decompose. The metal-free pump solves this environmental pain point by improving the pump core structure;

PCR recycled plastic use: Post-Consumer Recycled plastic is used to manufacture the pump head to reduce dependence on virgin plastics and add an environmental label to the brand;

Single material design (Monomaterial): The entire pump uses the same type of plastic material (such as all PP or all PE), which is convenient for users to classify in the recycling process;

Detachable pump structure: Users can easily disassemble the components of the pump head to achieve deep cleaning and repeated filling, extending the product life cycle;

Biological-based plastic attempts: Biomaterials such as PLA and sugarcane-based PE are initially used in pump housing production. Although the cost is high, it represents the future direction.

The rise of environmentally friendly pumps not only reflects responsibility, but is also increasingly becoming one of the selling points of high-end brands, especially in markets with strong environmental awareness such as Europe, the United States, and Japan.

5. Future Outlook: Intelligence and Personalization Coexist

The Plastic Screw Lotion Pump of the future will not only be "a pump", but also become part of the intelligent dispensing system and interactive interface. Several major development trends are brewing:

Intelligent dosage reminder: Through the electronic chip or mechanical counter integrated with the packaging, the number of times of use or dosage reminder can be realized;

Customized shape/pattern pump head: With the help of 3D printing or small batch injection molding technology, it can quickly respond to personalized customization needs, suitable for limited edition or gift box products;

Modular design: The pump head and bottle body structure are standardized and detachable, providing consumers with the possibility of free filling and multiple uses;

Fragrance/functional integrated pump: Integrate the fragrance release device or ultraviolet sterilization function into the pump body to add more value to the product;

Integration with electric pump: used for high-end skin care or precision proportioning scenarios, such as controlling the liquid discharge within 0.3ml each time, for high-value products such as eye cream and essence.

These new technologies will provide brands with stronger differentiated competitiveness while improving user experience.